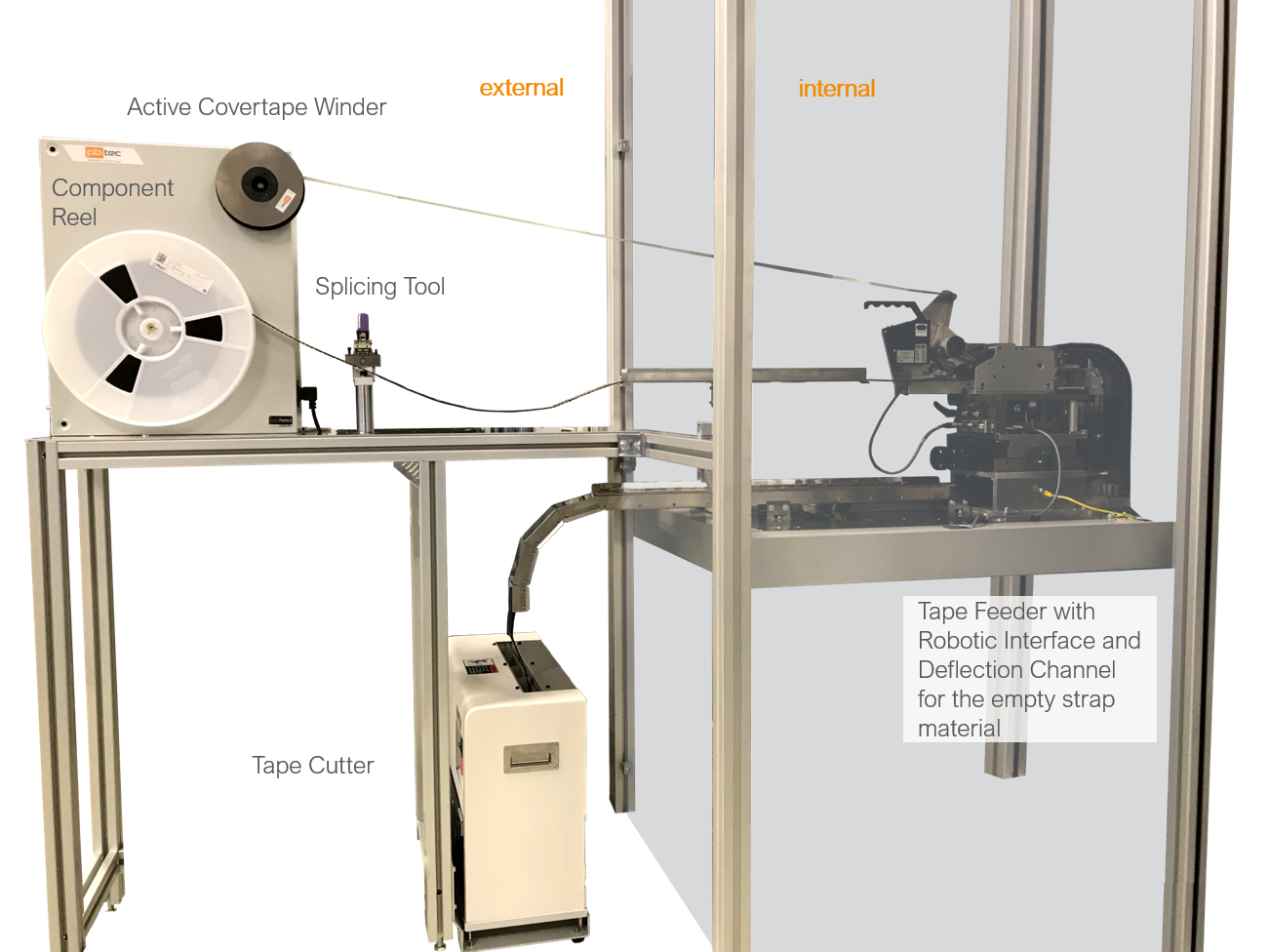

The safe solution for splicing the old to the new component reel outside the machine - without machine stop. The assembly cell can still be completely closed, as is often required for safety reasons.

Splicing is done manually on an external table with the help of a so-called Splicing Tool. The empty tape material is fed directly into a cutting device (Tape Cutter) via a deflection channel. The cover film is wound on an empty reel on the so-called Winder Station.

An important basic requirement for this external splicing is a modification of the Pocket Tape Feeder used to process the webbing material that has thickened in the splice area. Without this modification, the belt material can jam in the feeder in the area of the splice.

The splicing solution shown below can be modified and adapted as required: